Open beams allow for improved weld penetration, unobstructed visual inspection and no open voids collecting debris and corroding. Allows for repair to “as new” on structural joints.

Provides load impact support to internal plates and allows for easier main plate replacement for extended tray life if desired.

Solid steel edge support across entire width. Protects trailing edge of the floor plate from damage with limited to no maintenance required.

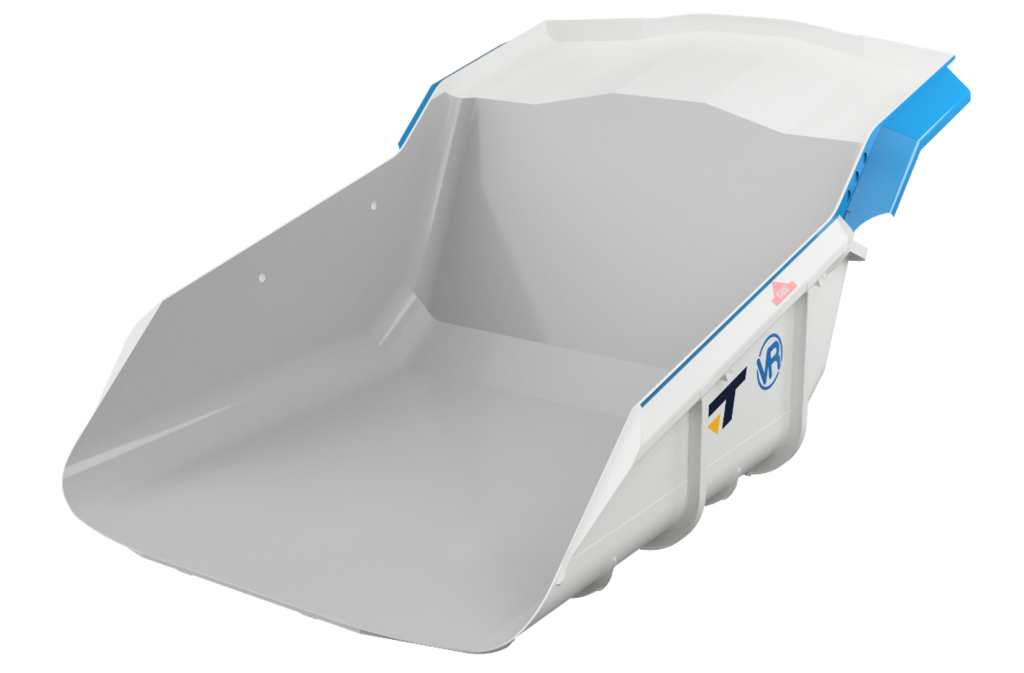

Improves berm clearance and reduces tail damage.

Pressed facia plate offers strength to canopy and spillage protection for stray rocks and debris.

Well supported front wall impact zone with continuous ribs reinforcing the front wall to canopy joint and providing exceptional support to overhanging canopy. Structural strength reduces risk in event of roll over.

Open structure – no concealed welds, allows for easy inspection and maintenance if required.

Reduces overall tray weight and promotes material flow with reduced carryback.

Upstanding canopy edge designed to retain material overflow and reduce spillage over front or sides. Upstand height customised to customers preference.

For optimal tray weight and material flow characteristics to suit the 100mt class truck chassis.

Internal side plate extends past top bolster with additional stiffener offering increased resistance to damage from rocks and loading tools.

Pressed plates add strength to the canopy with the raised center section following the load contour, reducing spillage.

Wrapped canopy rock deflectors provide protection to cab, deck, and side mirrors.

ENGINEERING

*Final Design weight subject to site specific conditions, required life expectancy, etc.